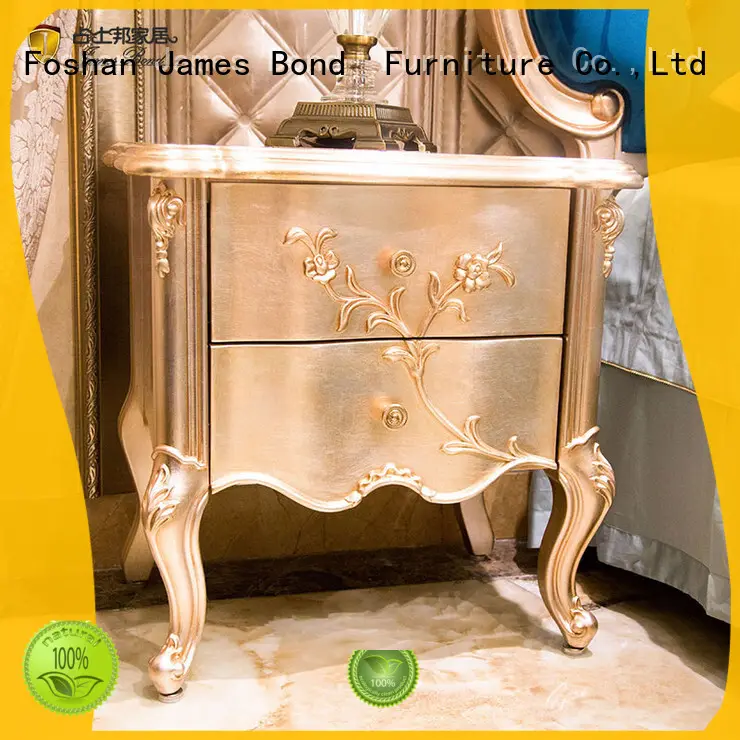

James Bond Classical bedside table designs 14k gold and solid wood JP615(golden)1

Place of Origin:

Foshan,China

Payment term:

T/T

MOQ:

1pcs

Model NO.:

JP615

Material:

Frenchbeech\Leather\14kgold

Description:

James Bond Classical bedside table designs 14k gold and solid wood JP615(golden)

Delivery Time:

golden

Brand Name:

60Wx43Dx63H

Company Advantages

1. James Bond Classical BedsideTable adopts a strict assembly process. This process includes adding solder paste to the PCB board, picking and placing components, and soldering.

2. The product is long-lived. Fabricated with high-grade electrical components, it can protect against short circuits, overload, high temperature, etc.

3. The product features user-friendliness. It has the desired functions that are developed based on the actual needs to support different kinds of operations.

4. The international market share of this product is increasing.

![James Bond Classical bedside table designs 14k gold and solid wood JP615(golden)1 11]()

![James Bond Classical bedside table designs 14k gold and solid wood JP615(golden)1 12]()

![James Bond Classical bedside table designs 14k gold and solid wood JP615(golden)1 13]()

![James Bond Classical bedside table designs 14k gold and solid wood JP615(golden)1 14]()

![James Bond Classical bedside table designs 14k gold and solid wood JP615(golden)1 15]()

![James Bond Classical bedside table designs 14k gold and solid wood JP615(golden)1 16]()

![James Bond Classical bedside table designs 14k gold and solid wood JP615(golden)1 17]()

![James Bond Classical bedside table designs 14k gold and solid wood JP615(golden)1 18]()

![James Bond Classical bedside table designs 14k gold and solid wood JP615(golden)1 19]()

![James Bond Classical bedside table designs 14k gold and solid wood JP615(golden)1 20]()

![James Bond Classical bedside table designs 14k gold and solid wood JP615(golden)1 21]()

![James Bond Classical bedside table designs 14k gold and solid wood JP615(golden)1 22]()

![James Bond Classical bedside table designs 14k gold and solid wood JP615(golden)1 23]()

![James Bond Classical bedside table designs 14k gold and solid wood JP615(golden)1 24]()

Company Features

1. James Bond transcends in Classical BedsideTable market.

2. In order to lead the Classical BedsideTable industry, James Bond invested a lot of money to absorb new technologies.

3. Our company adheres to the market-oriented. Ask! The strong aim of James Bond would be to function as future global 3 drawer bedside table supplier. Ask!

1. James Bond Classical BedsideTable adopts a strict assembly process. This process includes adding solder paste to the PCB board, picking and placing components, and soldering.

2. The product is long-lived. Fabricated with high-grade electrical components, it can protect against short circuits, overload, high temperature, etc.

3. The product features user-friendliness. It has the desired functions that are developed based on the actual needs to support different kinds of operations.

4. The international market share of this product is increasing.

Product information

Product process

1

Choose good quality French breech

2

Cut the wood into squares, and shape the wood

3

Wood is dried to be moisture content 8%-12% which is international standard.

4

Manual carve patterns or designs on woodwork

5

Piece wood together assembly into a semi-finished product

6

Pure hand-cut, bottle stick natural wood veneer

7

Polishing the semi-finished product

8

Hand-pasted 14k gold foil

9

Accurate installation of finished products

10

Packing

Company Features

1. James Bond transcends in Classical BedsideTable market.

2. In order to lead the Classical BedsideTable industry, James Bond invested a lot of money to absorb new technologies.

3. Our company adheres to the market-oriented. Ask! The strong aim of James Bond would be to function as future global 3 drawer bedside table supplier. Ask!

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Contact us

we welcome custom designs and ideas and is able to cater to the specific requirements. for more information, please visit the website or contact us directly with questions or inquiries.

you might like

no data