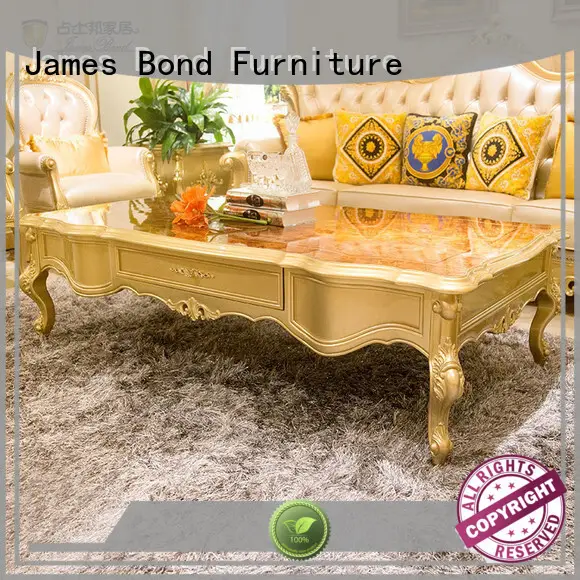

James Bond excellent traditional wood coffee tables series for hotel

Useful Lifetime:

10-15 years

Price Term:

EXW, FOB Foshan, CIF, Door to door

Place of Origin:

Foshan, China

Payment term:

T/T, L/C, Others

MOQ:

1pcs

Model NO.:

JF513

Material:

French beech

Description:

Classic Brown 14k gold and solid wood with piano resin paint coffee able

Delivery Time:

38 working days after confirmed drawing and received 40%deposit

Brand Name:

James Bond

Company Advantages

1. Production processes of James Bond traditional wood coffee tables mainly include several parts: fibers preparation, washing, loosening, fabric dyeing, combing, and others. Its classical style has a high sense of decorative purpose

2. Foshan James Bond Furniture Co.,Ltd has a professional team to provide tailor-made services according to customer's required size and style. The product is firmly assembled and installed manually

3. The product is built to last. Its sturdy frame can keep its shape over the years and there’s no variation that could encourage warping or twisting. Its carved patterns and designs are all hand-made

![James Bond excellent traditional wood coffee tables series for hotel 11]()

![James Bond excellent traditional wood coffee tables series for hotel 12]()

![James Bond excellent traditional wood coffee tables series for hotel 13]()

![James Bond excellent traditional wood coffee tables series for hotel 14]()

![James Bond excellent traditional wood coffee tables series for hotel 15]()

![James Bond excellent traditional wood coffee tables series for hotel 16]()

![James Bond excellent traditional wood coffee tables series for hotel 17]()

![James Bond excellent traditional wood coffee tables series for hotel 18]()

![James Bond excellent traditional wood coffee tables series for hotel 19]()

![James Bond excellent traditional wood coffee tables series for hotel 20]()

![James Bond excellent traditional wood coffee tables series for hotel 21]()

![James Bond excellent traditional wood coffee tables series for hotel 22]()

![James Bond excellent traditional wood coffee tables series for hotel 23]()

![James Bond excellent traditional wood coffee tables series for hotel 24]()

Company Features

1. Foshan James Bond Furniture Co.,Ltd currently has a research and development center and a large-scale production base.

2. Foshan James Bond Furniture Co.,Ltd is equipped with complete equipment, complete testing means, and perfect quality assurance system.

3. Our customer-first core value is deeply rooted in all aspects of the James Bond business. Get info!

1. Production processes of James Bond traditional wood coffee tables mainly include several parts: fibers preparation, washing, loosening, fabric dyeing, combing, and others. Its classical style has a high sense of decorative purpose

2. Foshan James Bond Furniture Co.,Ltd has a professional team to provide tailor-made services according to customer's required size and style. The product is firmly assembled and installed manually

3. The product is built to last. Its sturdy frame can keep its shape over the years and there’s no variation that could encourage warping or twisting. Its carved patterns and designs are all hand-made

Product information

Product process

1

Choose good quality French breech

2

Cut the wood into squares, and shape the wood

3

Wood is dried to be moisture content 8%-12% which is international standard.

4

Manual carve patterns or designs on woodwork

5

Piece wood together assembly into a semi-finished product

6

Pure hand-cut, bottle stick natural wood veneer

7

Polishing the semi-finished product

8

Hand-pasted 14k gold foil

9

Accurate installation of finished products

10

Packing

Company Features

1. Foshan James Bond Furniture Co.,Ltd currently has a research and development center and a large-scale production base.

2. Foshan James Bond Furniture Co.,Ltd is equipped with complete equipment, complete testing means, and perfect quality assurance system.

3. Our customer-first core value is deeply rooted in all aspects of the James Bond business. Get info!

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Contact us

we welcome custom designs and ideas and is able to cater to the specific requirements. for more information, please visit the website or contact us directly with questions or inquiries.

you might like

no data