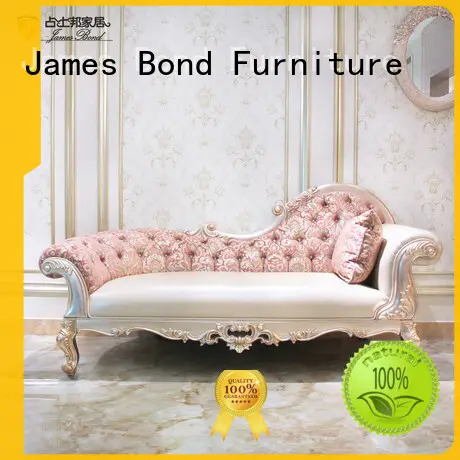

James Bond Custom right arm chaise factory for business

Useful Lifetime:

10-15 years

Seat material:

Leather/cloth

Price Term:

EXW, FOB Foshan, CIF, Door to door

Place of Origin:

Foshan,China

Payment term:

T/T, L/C, Others

MOQ:

1pcs

Model NO.:

E193

Material:

Frenchbeech\Leather\14kgold

Description:

James Bond Classic chaise longue design rose gold and solid wood E193

Delivery Time:

38 working days after confirmed drawing and received 40%deposit

Brand Name:

James Bond

Product information

Product process

1

Choose good quality French breech

2

Cut the wood into squares, and shape the wood

3

Wood is dried to be moisture content 8%-12% which is international standard.

4

Manual carve patterns or designs on woodwork

5

Piece wood together assembly into a semi-finished product

6

Pure hand-cut, bottle stick natural wood veneer

7

Polishing the semi-finished product

8

Hand-pasted 14k gold foil

9

Accurate installation of finished products

10

Packing

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Contact us

we welcome custom designs and ideas and is able to cater to the specific requirements. for more information, please visit the website or contact us directly with questions or inquiries.

you might like

no data